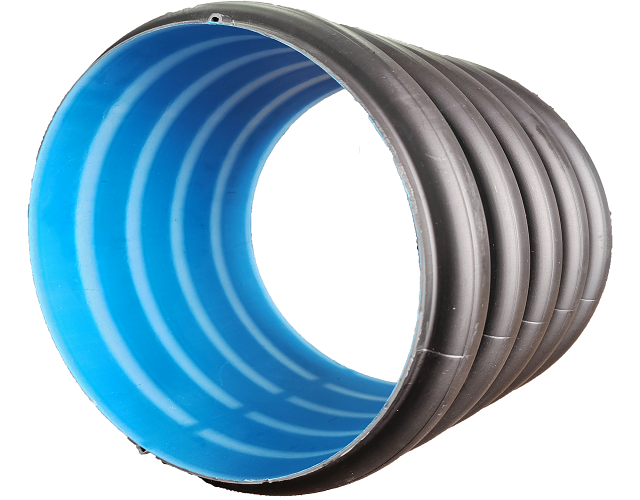

Pressure-resistant HDPE Socket Hollow Wound Pipe used for rainwater harvesting system

Ideal for high-pressure applications, this HDPE pipe boasts exceptional strength and flexibility, making it a preferred choice for municipal projects.

Email:

info@hn-guangqun.com

Phone:

+86-13838155309

Detailed Product Description

Hollow Wound Pipe Specification:

| Execution Standard | GB/T19472.1-2019 |

| Ring Stiffness Rating | SN4≥4kN/m²,SN8≥8kN/m²,SN12.5≥12.5kN/m² |

| Nominal Diameter | 160 200 300 400 500 600 800 |

| Connection Method | Socket-type rubber ring seal connection |

| Length | 6m/unit |

Hollow Wound Pipe Description:

The HDPE (High-Density Polyethylene) Spigot & Socket Hollow Winding Pipe is an innovative and highly efficient piping system designed for a wide range of applications requiring superior durability, flexibility, and cost-effectiveness. This advanced product leverages the exceptional properties of HDPE material, known for its resistance to corrosion, chemicals, and environmental stress, making it an ideal choice for various infrastructure projects.Hollow Winding Pipe Basic Features:

Material and structure: HDPE Socket Hollow Winding Pipe is made of HDPE as raw material and adopts special winding technology, which has a hollow structure. This kind of pipe not only inherits the excellent performance of HDPE material, but also enhances its overall performance through the unique winding method.

Corrosion resistance: The pipe has strong corrosion resistance, able to resist the erosion of many chemicals such as acid, alkali, salt, etc. It is also resistant to the corrosion of sewage, wastewater and chemicals, as well as the corrosion of decayed materials in the soil.

Physical properties: Socket type hollow winding pipe has high toughness and resistance to bending and stretching, strong impact resistance and excellent pressure resistance. Its pipe wall adopts I-beam structure, with large elastic deformation but not easy to destroy, and it has good applicability to any base.