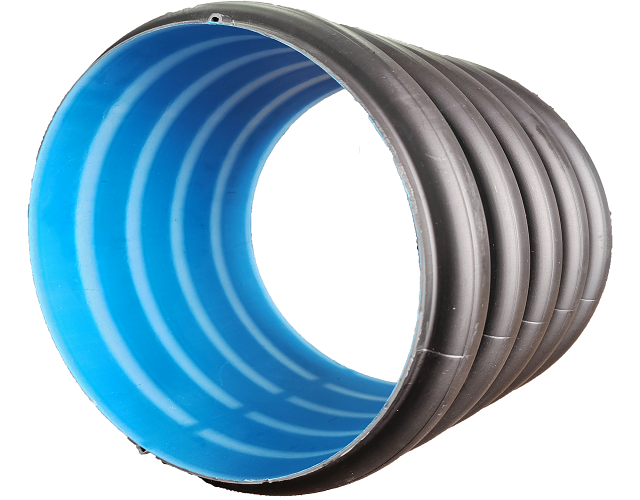

Industrial-Grade HDPE Hollow Wound Pipe for Heavy-Duty Wastewater Treatment

Reinforced HDPE pipes designed for high-pressure, heavy-duty wastewater treatment applications.

Email:

info@hn-guangqun.com

Phone:

+86-13838155309

Detailed Product Description

Hollow Wound Pipe Features:

Strong Corrosion Resistance

High Insulation Properties

Smooth Inner Wall and Low Flow Resistance

Excellent Ring Stiffness and Good Strength & Toughness

Lightweight

Strong Impact Resistance and Durability

Long Service Life

Cost-Effective

Convenient Transportation and Installation

Hollow Wound Pipe Specification:

| Execution Standard | GB/T19472.1-2019 ,ISO13968:2008 |

| Ring Stiffness Rating | SN4≥4kN/m²,SN8≥8kN/m²,SN12.5≥12.5kN/m² |

| Nominal Diameter | 160 200 300 400 500 600 800 |

| Connection Method | Socket-type rubber ring seal connection |

| Length | 6m/unit |

Hollow Wound Pipe Connection method:

Socket connection: insert the bellows socket into another section of bellows socket and connect by socket. This kind of connection has the advantages of reliable connection, convenient construction and good sealing performance.

Heat fusion connection: The two bellows are fused together by high temperature, which makes the pipe wall completely fused and achieves the sealing effect. This type of connection has high connection strength, good sealing performance and high temperature resistance.

Electrofusion connection: The wall of the pipe is fused together by heating of electric wire. This type of connection is simple, reliable and easy to construct.

Clamp connection: two bellows are fixed together by metal clamp. This kind of connection is simple to install, easy to dismantle and has good sealing performance.