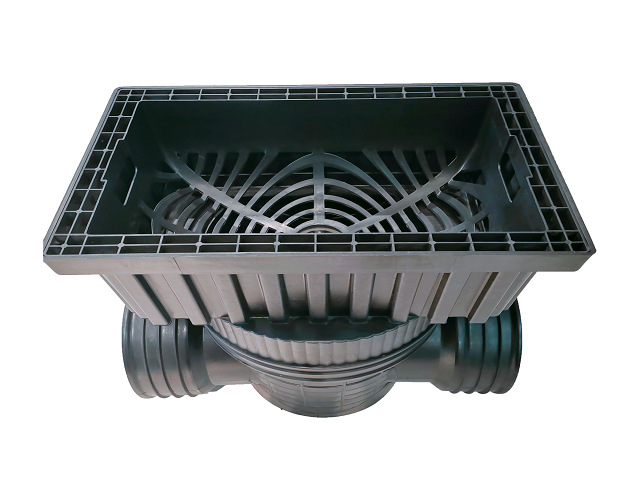

Maintenance-Friendly Access Plastic Inspection Chamber

Inspection Chamber are designed with strong yet lightweight plastic for easy access and maintenance of underground piping systems.

Email:

info@hn-guangqun.com

Phone:

+86-13838155309

Detailed Product Description

Inspection Chamber are used in construction districts (residential areas, public buildings, factories, etc.) within the scope of the buried plastic drainage pipes with an outside diameter of not more than 800mm, buried depth of not more than 6m, generally located in the drainage pipe intersection, turning, pipe diameter or slope change, water fall, etc., for the city's underground infrastructure, power supply, water supply, drainage, sewage disposal, communications, cable television, gas pipes, street light lines, such as maintenance, installation and convenient installation of plastic injection molded well-like structures. Installation is convenient and set up a plastic injection molded well structure.

Inspection Chamber Features:

- Acid and alkali corrosion resistance and aging resistance: Polymer materials, long service life; unique design of reinforcement, increasing the friction between the well body and the soil, to achieve the effect of anti-uneven settlement and anti-floating;

- Safety and environmental protection: Plastic inspection wells are made of high-density polyethylene plastic non-toxic odorless, recyclable after use.

- Uniform settlement, pressure resistance: Flexible connection between the pipe and the well base, the pipe and the clay of the well base move together, preventing the ground from collapsing

- Construction is convenient and quick: Adopting split assembly structure, the shaft can be cut and adjusted on the spot, adapting to the requirements of various installation depths, and effectively reducing the cost.

- Efficient drainage: The inner wall is smooth and fluent, equipped with guide groove, dirt is not easy to be retained, the discharge rate is 1 to 3 times of the traditional inspection wells.

- Good sealing performance, leakage prevention: The use of flexible connection, flexible and convenient, can overcome the wind, dust, sand and dust of the harsh construction environment, to prevent leakage of rainwater and sewage leakage, in order to prevent groundwater pollution.

- Saving materials: Plastic inspection wells by polymer resin as a processing material instead of red brick cement, saving topsoil resources; construction of the community used to narrow the specifications, greatly saving the land space occupied by the inspection well buried.

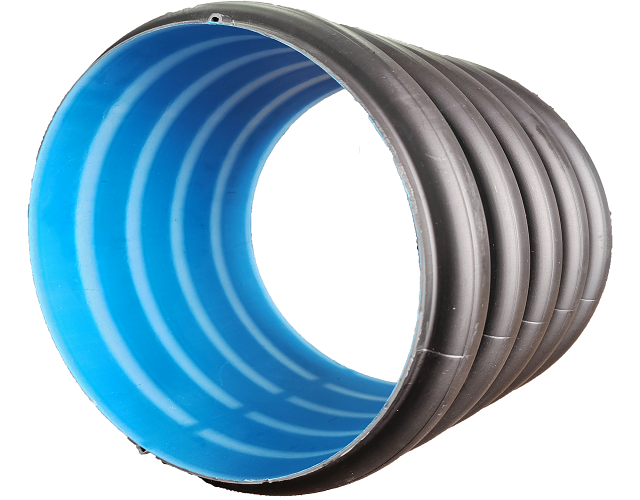

- Strong adaptability: According to the height of the actual project needs, in the well seat inserted finished pipe (winding pipe, corrugated pipe, steel-plastic pipe, glass fiber reinforced plastic pipe can be).

- Suitable for building district (residential area, public building area, factory, etc.) within the scope of the buried depth is not greater than 6m, not down the well operation of plastic drainage check well project design, construction and maintenance.

- General soil, soft soil, permanent frozen soil, seasonal frozen soil, expansive soil and humid loess soil conditions under the construction of plastic drainage check wells.

- Areas where the seismic cracking degree is 9 and below.

- Groundwater level is designed not higher than 1.0m below the ground.