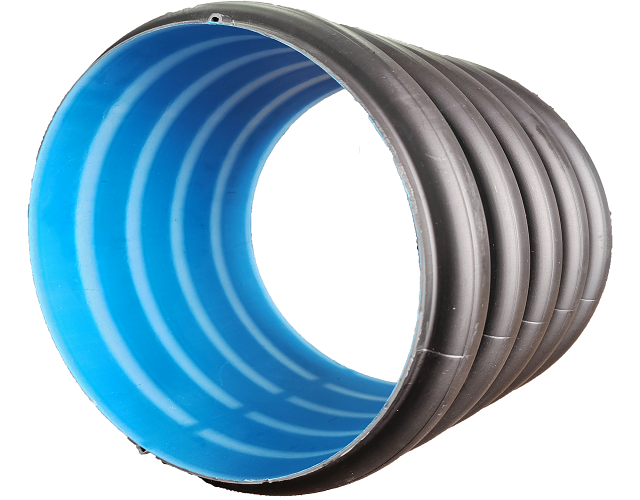

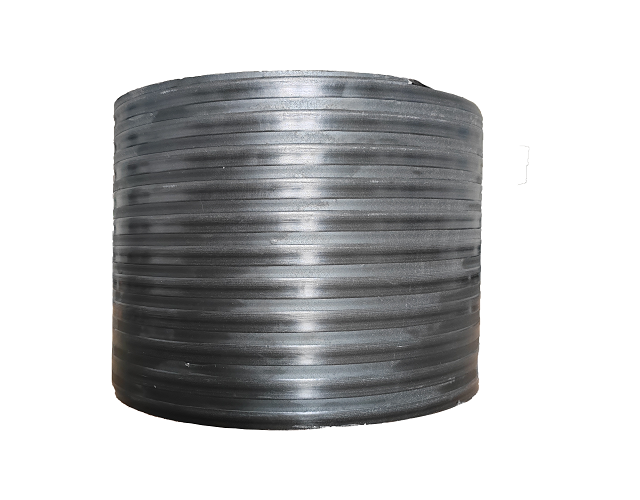

HDPE Large Diameter Hollow Wall Winding Pipe

A high-density polyethylene pipe designed for large-scale water transportation, offering durability, corrosion resistance, and easy installation.

Email:

info@hn-guangqun.com

Phone:

+86-13838155309

Detailed Product Description

Winding Pipe Specification:

| Execution Standard | GB/T19472.1-2019 |

| Ring Stiffness Rating | SN4≥4kN/m²,SN8≥8kN/m²,SN12.5≥12.5kN/m² |

| Nominal Diameter | 160 200 300 400 500 600 800 |

| Connection Method | Socket-type rubber ring seal connection |

| Length | 6m/unit |

Winding Pipe Features:

Chemical Stability & Corrosion Resistance: Acid, Alkali, Salt, Sewage Resistant

Impact & Pressure Resistance: I-Beam Structure, Elastic Deformation

Aging Resistance: Sunlight Tolerant, 50-Year Durability

Wide Temperature Range: -50°C to 60°C Tolerant

Lightweight: 1/10 Weight of Cement Pipe

Easy Connection

Superior Abrasion Resistance: 50+ Year Lifespan

Cost-Effective: Low Raw Material & Maintenance Costs

Environmentally Friendly: Non-Toxic, Renewable Use

How to connect pipes to each other?

Rubber ring socket connection is a kind of connection method to realize pipe sealing through rubber sealing ring.

- Preparation: Ensure that the pipe, sealing ring and tools are complete, and check that the pipe and sealing ring are not damaged.

- Cleaning: Clean the debris on the surface of the pipe socket and keep it clean.

- Install the seal: Install the rubber seal correctly on the socket end.

- Lubrication: Apply the proper amount of lubricant to the seal and the inside of the socket.

- Mating: Slowly advance the socket against the socket until it reaches the intended position.

- Inspection: Check whether the seal ring is evenly pressurized to ensure the sealing effect.