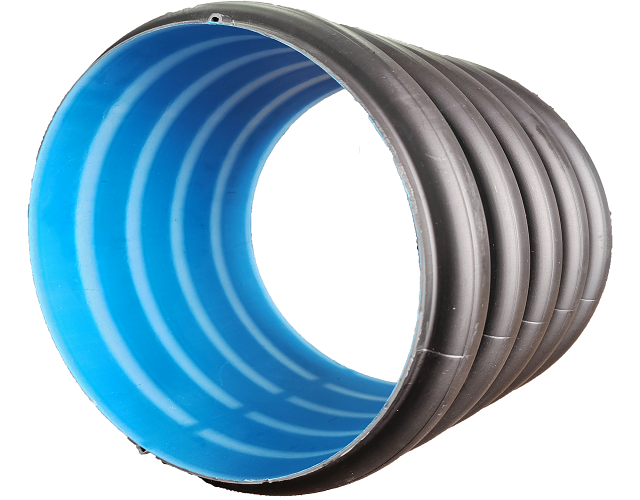

HDPE Socket Hollow Winding Pipe for Durable Municipal Drainage

Our HDPE socketed hollow-wound pipes provide reliable, long-lasting municipal drainage solutions with their robust construction and seamless connections.

Email:

info@hn-guangqun.com

Phone:

+86-13838155309

Detailed Product Description

High Density Polyethylene (HDPE) socketed hollow-wound pipes are widely used in applications where durability, flexibility and cost-effectiveness are paramount. This state-of-the-art product capitalises on the excellent properties of the HDPE material, known for its resistance to corrosion, chemicals and environmental stresses, making it ideal for a wide range of infrastructure projects.

Winding Tube Specification:

| Execution Standard | GB/T19472.1-2019 |

| Ring Stiffness Rating | SN4≥4kN/m²,SN8≥8kN/m²,SN12.5≥12.5kN/m² |

| Nominal Diameter | 160 200 300 400 500 600 800 |

| Connection Method | Socket-type rubber ring seal connection |

| Length | 6m/unit |

Winding Tube Features:

Chemical Stability & Corrosion Resistance: Acid, Alkali, Salt, Sewage Resistant

Impact & Pressure Resistance: I-Beam Structure, Elastic Deformation

Aging Resistance: Sunlight Tolerant, 50-Year Durability

Wide Temperature Range: -50°C to 60°C Tolerant

Lightweight: 1/10 Weight of Cement Pipe

Easy Connection

Superior Abrasion Resistance: 50+ Year Lifespan

Cost-Effective: Low Raw Material & Maintenance Costs

Environmentally Friendly: Non-Toxic, Renewable Use

Winding Tube Application:

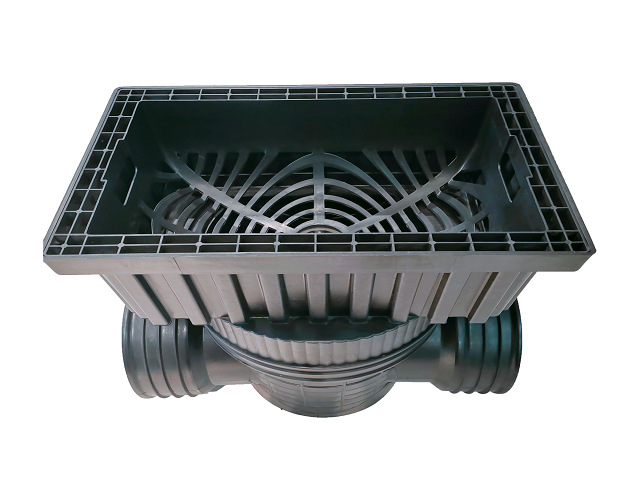

1, municipal drainage, sewage pipe system engineering;

2, apartments, residential district underground buried drainage sewage;

3, highway buried pipeline, golf course underground seepage pipe network;

4, agricultural irrigation water transfer, drainage and other water conservancy projects;

5, chemical industry, mines for the transmission of fluids and ventilation, etc.;

6, underground pipeline protection casing and communication cable sheathing.