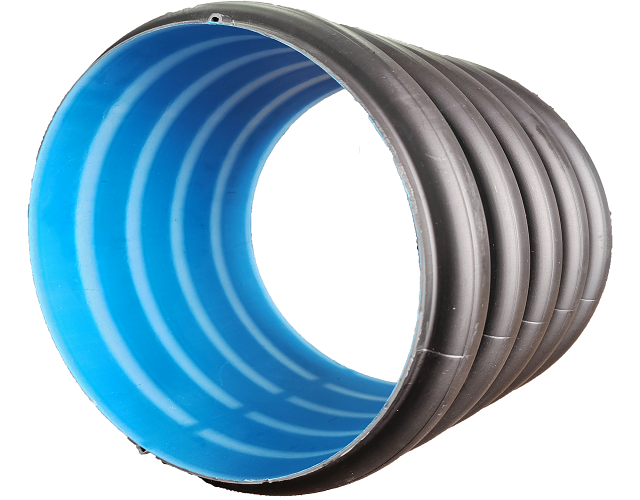

HDPE Socket Hollow Winding Pipe

Engineered for durability, flexibility, and cost-effectiveness, it is resistant to corrosion,and environmental stress, making it ideal for municipal drainage and sewage pipe system engineering.

Email:

info@hn-guangqun.com

Phone:

+86-13838155309

Detailed Product Description

HDPE Socket Hollow Winding Pipe is a kind of pipeline product made of high-density polyethylene (HDPE) as raw material, through winding, welding and other processes. With unique structural design and excellent physical properties, the pipe is widely used in many fields such as municipal drainage, sewage, agricultural irrigation, construction engineering and communication engineering.

Specification:

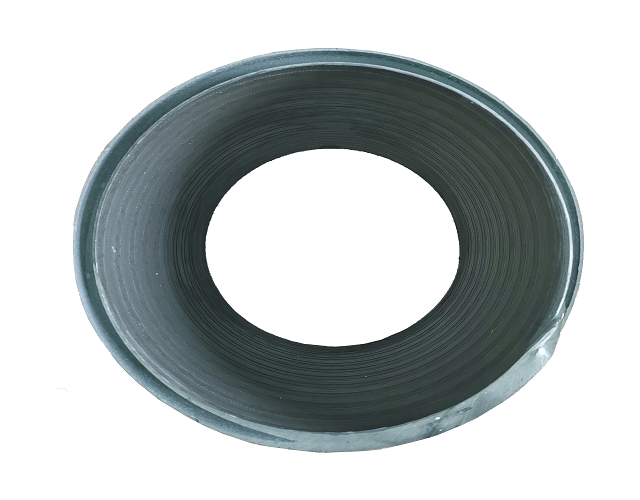

Execution Standard GB/T19472.1-2019 Ring Stiffness Rating SN4≥4kN/m²,SN8≥8kN/m²,SN12.5≥12.5kN/m² Nominal Diameter 160 200 300 400 500 600 800 Connection Method Socket-type rubber ring seal connection Length 6m/unit

Production process:

- Preparation of raw materials: choose high quality HDPE raw materials.

- Melt Extrusion: The raw material is melted and extruded in the extruder to form the plastic profiled rectangular pipe.

- Cooling and shaping: The molten profiled rectangular pipe is cooled and shaped by spraying water tank or natural cooling.

- Winding molding: Wind the cooled profiled rectangular pipe on the mold of specified caliber, and inject the molten HDPE resin into the mold through the injection molding machine, so that the winding profiled rectangular pipe is fused into a pipe under the state of full fusion between each other.

- Cooling and shaping: The fusion-molded pipe is fully cooled and shaped.

- Cutting and inspection: The pipe is cut into the required length by automatic cutting machine and quality inspection is carried out to ensure that all the indexes of the pipe are in accordance with the national standards.

- Storage: Qualified pipes are stored in the warehouse, waiting for shipment or installation.