Suitable Installation Height for Fixed Gas Detectors

Published on: 2024-08-02 Views: 851

In industrial production, laboratory research and daily life, fixed gas detectors are important equipment for safety monitoring, and the choice of their installation height is directly related to the monitoring effect and safety. Different types of gases have different requirements for the installation height of the detector due to their physical properties (such as density, volatility, etc.).

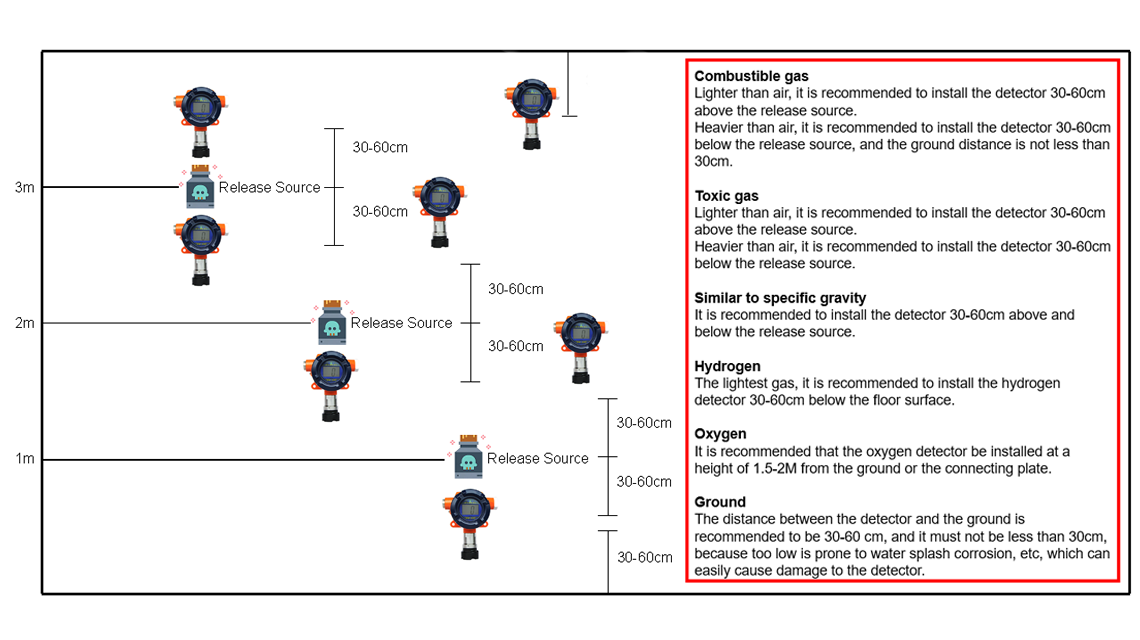

1. Combustible or toxic gases heavier than air

For flammable or toxic gases heavier than air (such as hydrogen sulfide, carbon dioxide, etc.), since their density is greater than that of air, they are easy to accumulate in low-lying areas. Therefore, the installation height of the detector should be appropriately lowered to ensure that the concentration of these gases can be accurately monitored.

Recommended installation height: 0.3m to 0.6m from the floor (or floor). This height range not only avoids damage caused by rain splashing, but also ensures that the detector can be in an area where gas is easy to accumulate.

Note: Avoid low-lying and water-prone areas to prevent the detector from being damaged by moisture.

2. Combustible or toxic gases lighter than air

Combustible or toxic gases lighter than air (such as methane, hydrogen, etc.) are easy to diffuse at high places because their density is lower than that of air. Therefore, the installation height of the detector should be increased accordingly.

Recommended installation height: 0.5m~2m above the release source. For gases with extremely fast diffusion speed such as hydrogen, it is recommended to install it around and within 1m above the release source to ensure timely monitoring of gas leakage.

Note: The installation location should fully consider the diffusion direction and speed of the gas to ensure that the detector can capture the earliest gas leakage signal.

3. Gases slightly heavier or lighter than air

For gases with a density similar to that of air, the choice of installation height needs to be more flexible.

Slightly heavier gas: The installation height should be 0.5m~1m below the release source to ensure that the detector can be in the area where the gas may accumulate.

Slightly lighter gas: The installation height should be 0.5m~1m above the release source to capture the initial signal of gas diffusion.

4. Environmental oxygen detector

The environmental oxygen detector is mainly used to monitor the oxygen concentration in the air to prevent dangerous situations such as hypoxia or oxygen enrichment.

Recommended installation height: 1.5m to 2.0m from the floor or floor. This height range is convenient for personnel to observe and maintain, and can ensure that the detector can accurately reflect the oxygen concentration in the environment.

The installation height of the fixed gas detector should be comprehensively considered based on the physical properties, diffusion characteristics and surrounding environment of the monitored gas. Reasonable installation height can ensure that the detector operates in the best working state, timely and accurately monitor gas leaks or concentration changes, and provide strong protection for production safety and personnel health.